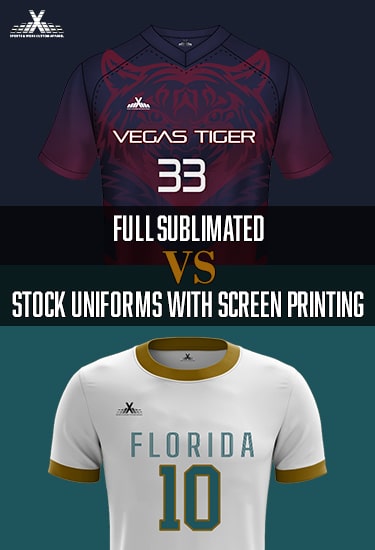

Full Sublimated vs. Stock Uniforms with Screen Printing

Big brands use “stock” uniforms as a budget-friendly way to outfit sports teams in the US. Stock uniforms are the best option if you want to design and style your own customization. Later, you can customize them with your logo, team name, or player number through screen printing. However, the emergence of new customization techniques has brought many options you can select according to your budget and requirement.

The last time you ordered uniforms for your team, your supplier might have asked if you wanted full sublimated sports uniforms or screen printing. To help you make an informed and sure decision, we have shed light on the pros and cons for each. The information will enlighten you about the most suitable option before you place your next order.

Sublimation: Pros and Cons

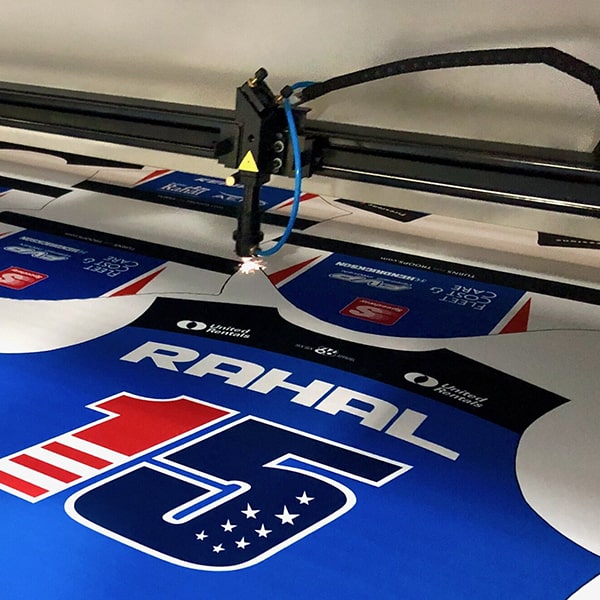

Sublimation is a customization process that transforms the complete jersey according to your chosen design. The logos, colors, and designs are put on a garment through ink injection.

The sublimation ink turns into a gaseous form. This gas is directly injected into the fabric and becomes part of the material. You can either sublimate the entire or a part of the garment, regardless of the material. Sublimation works well on almost every performance fabric in the market.

Pros

There is no color chipping, fading, or smudging.

You get unlimited options and flexibility in design. You can design your jerseys with anything you imagine.

It is cost-effective for large designs and those with multiple colors.

Cons

Since sublimation is done on a white canvas, you can witness picks and pulls if not done carefully.

It takes time to sublimate fabric, so the turnaround time is longer compared to printing.

It works on all types of performance fabric, but the material must have at least 65% of polyester.

Sublimated garments are recyclable but not 100%.

Screen Printing: Pros and Cons

Screen Printing is done by printing a design using silkscreen ink on the garment through a screen. When screen printing, you put the design as a layer over the garment. Each color is then “screened” individually.

Pros

It is highly cost-effective for single-color designs.

It is best suitable for 100% cotton or blended material so that you can print not only sports jerseys but other types of garments too.

It’s great for large, single-color designs and bulk orders.

Cons

Screen printed colors and designs often peel, crack, or fade over time.

It limits you to a single color and simple designs per garment.

It is expensive if not used for large bulk orders.

Why Sublimation?

If we weigh the pros and cons of both the customization technique, sublimation will win over screen printing. The reason, as per the mentioned pros and cons, is that the process suits performance material is cost-effective for bulk orders and provides unlimited design options.

The Garment Lasts Longer

The ink becomes gas and infiltrates the garment completely, becoming a part of the fabric. Therefore, it is less likely for the design and clothing to fade, chip, or peel off. The outcome is a lighter, cleaner, and long-lasting uniform for your sports team and performance.

Endless Possibilities of Designs and Colors

Whether we sublimate 10 or 100, the process and set-up remain the same. You can place the designs anywhere on a garment. Sublimation can pour any design of your imagination with unlimited colors and patterns. So, suppose you think beyond a single logo on your team’s uniforms and want to make the entire jersey your symbol. In that case, sublimation is the best option for you.

No Extra Costs

The cost increases with each pattern or design you print on the garment through screen printing. However, sublimation enables you to print even the most complicated single or multiple designs in one piece. Therefore, you don’t have to pay extra for added colors or designs.

Easy Reorders of Bulk Supply

Another advantage of choosing sublimation over other printing methods is that you can easily reorder bulk supplies. For instance, if you add another player to your team or a player loses a jersey, you can order the same item without the need to pay set-up costs.

Changes to NFL Numbering Rules: NFL had allotted fresh number ranges to various position groups of the players for new sessions. Particularly, for running backs, tight ends, and receivers new number brackets tripled the number of options for an individual player.

Before this new numbering system, the knickers, punters, and quarterbacks had single-digit jersey numbers. In the new numbering system, the group has extended including defensive backs, running backs, wide receivers, and tight ends. The breakdown of this new numbering system is here:

Even before this, in 1984, two major changes took place to this number system. These changes were necessary to make up for the lack of numbers allotted to a single position. In this context, NFL allowed numbers 90 to 99 for the linebackers and defensive linemen. Many other teams wish to choose a base 3 to 4 defense. Before this alteration, only 50 to 59 numbers defined the linebackers.

In 2004 another change occurred in the numbering system. The major reason behind this was that the respective teams of very high-profile receivers retired their numbers. In response to this action, the NFL authorities had to allow wide receivers to wear numbers between 10 to 19 too. Though the numbers associated with them before this were only 80 to 89. Keyshawn Johnson, a famous wide receiver, had been paying fines willing for wearing number 19 long before this alteration.

Frequently Asked Question

Does Sublimation Take a Long Time?

Sublimation has improved greatly over the years. In addition, with technological advancements in the processes, the turnaround time of fully sublimated garments has been reduced to four weeks or even less.

Does Sublimation Cost More?

If you check the market, you will find that almost every vendor sells screen-printed and sublimated garments at equal prices. However, if you order screen printing, the cost will increase with every color, design, or number you would add to the garment. Therefore, it can significantly increase the cost. On the other hand, in sublimation, you don’t have to worry about additional costs for added colors or elements. Moreover, the designs last longer, making sublimation a very cost-effective option.

The last words

The stock uniforms with screen printing are typically used by middle schools and teams with low budgets. US brands like A4, Augusta, and Russel Athletics sell stock uniforms of all sizes and colors. However, as soon as you get into larger programs, or D1 or D2 level, you will have to reconsider your options. Full Sublimated Custom uniforms become the only way to go. Comparing the screen printing and sublimation processes, it is evident that sublimation is the best option for sports uniforms and all types of performance fabrics.